Definitions and basic components

Definitions and basic Wheel components

A Wheel consists of tread, centre, hub and bearing.

Swivel castors rotate around the vertical axis, ensuring manoeuvrability and stability, and can be fitted with different locking systems.

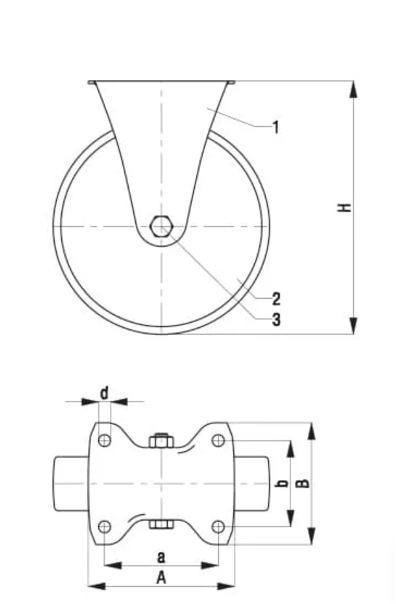

Fixed castors are not steerable and are designed for straight-line travel.

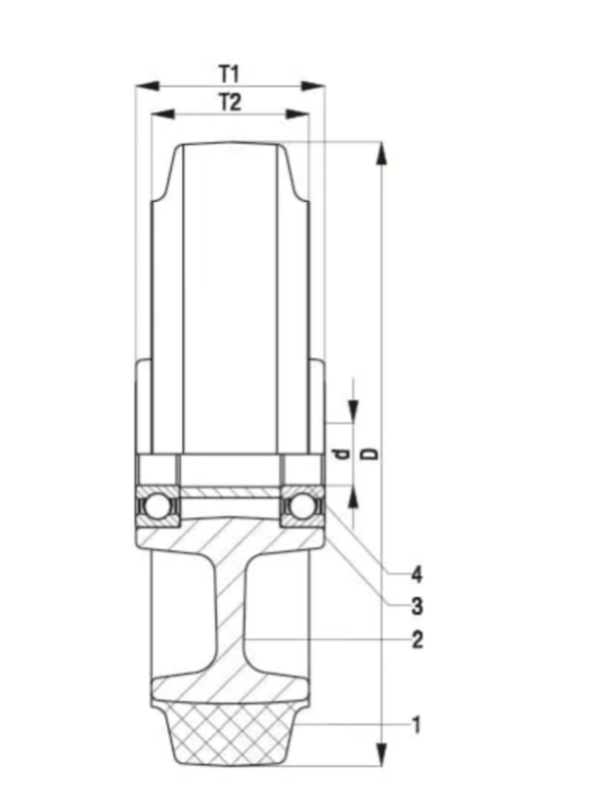

Wheel

A Wheel is composed of tread, centre and hub.

The different Wheel types are distinguished by load capacity, rolling resistance and running characteristics.

The specific features of each Wheel series are described in detail in the corresponding section.

Nomenclature:

1 = tread

2 = centre

3 = hub

4 = Wheel bearing

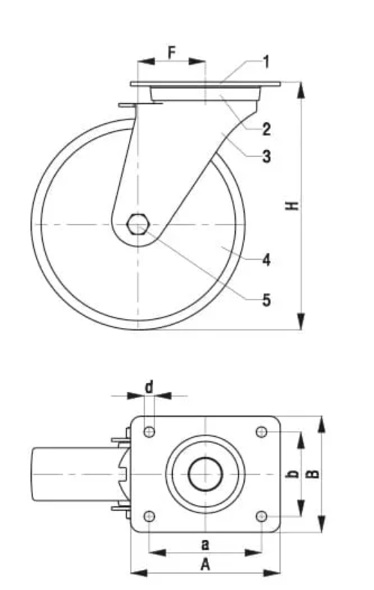

Swivel castor

Nomenclature:

1–3 = swivel castor

1 = top plate

2 = swivel head (swivel bearing)

3 = swivel fork

4 = Wheel

5 = axle

Dimensions:

H = overall / installation height

F = offset

A, B = top plate dimensions

a, b = hole spacing

d = fixing hole diameter

Swivel castors rotate vertically, allowing machines and equipment to be manoeuvred easily.

The swivel head connects the fork to the fixing element.

The swivel bearing axis is normally positioned at a horizontal distance from the Wheel axle (offset), which facilitates fork rotation.

This offset enables smooth rotation without additional devices while ensuring stability in straight travel.

Swivel castors can be fitted with:

- wheel lock (Wheel rotation only)

- total lock (Wheel and swivel head rotation)

- directional lock (swivel movement only)

For further technical details or to request tailored advice: