Selection

guide

Correct selection of Wheels and rollers: type, load capacity and operating conditions

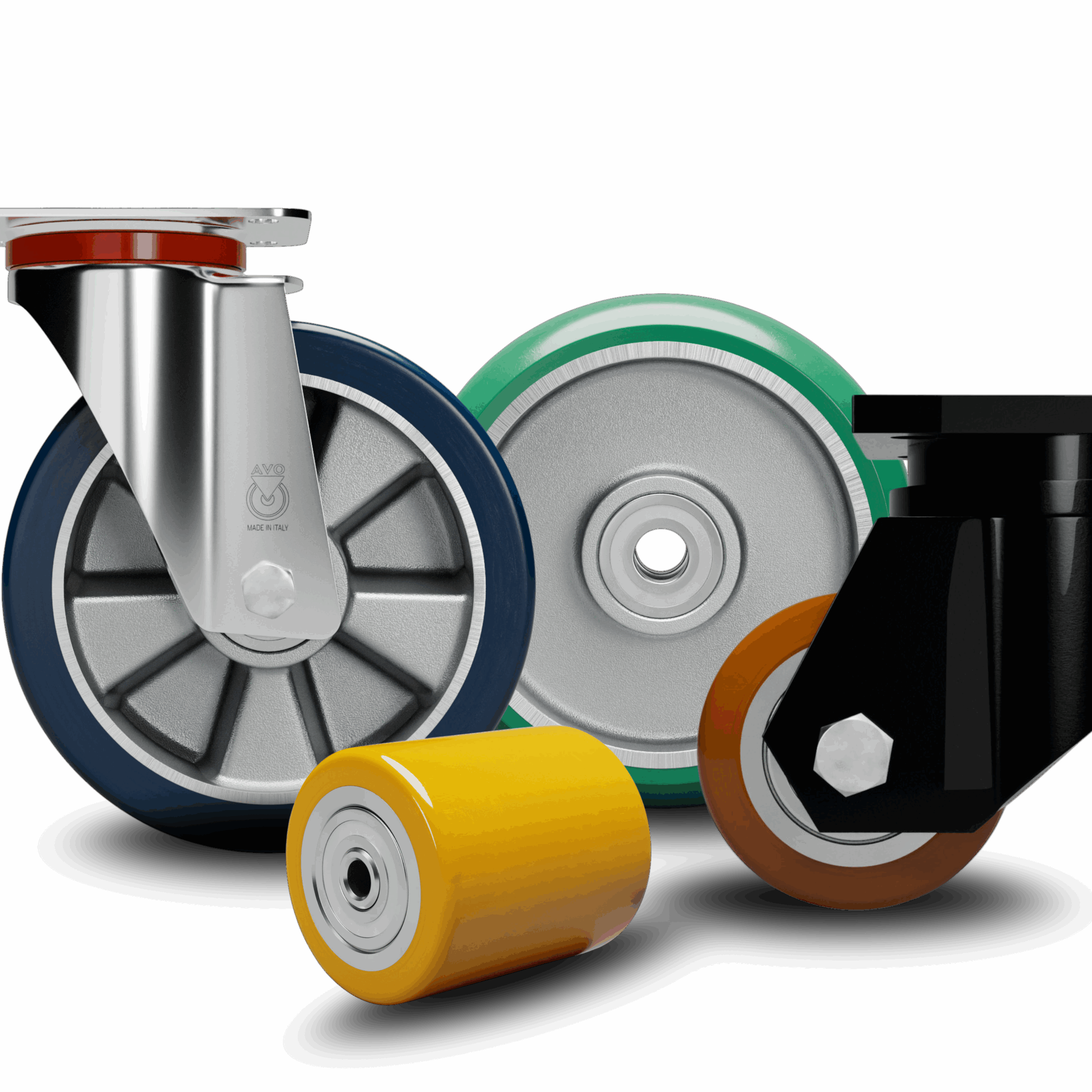

Selecting Wheels and rollers requires more than a simple mechanical evaluation: it involves defining the type (single Wheel, castor, roller), calculating the required load capacity with a safety factor, and considering environment, temperature, flooring, and hygiene. The choice of materials, hubs, brackets, and accessories ensures safety, durability, and efficiency.

1. Product type selection

- Single Wheel: used as a component in existing structures or machinery.

- Wheel with castor bracket: available in swivel or fixed version, provides optimal load capacity and maneuverability for trolleys and equipment.

- Roller: ideal for internal handling and continuous transport systems.

- Roller with bracket: used for heavy-duty applications or where direct installation is needed.

2. Determining the required load capacity

After identifying the product type, it is essential to establish the required load capacity based on operating conditions. The correct value must take into account:

- The tare weight of the trolley or equipment

- The maximum load to be transported

- The number of Wheels or rollers installed

3. Evaluating environmental factors and operating conditions

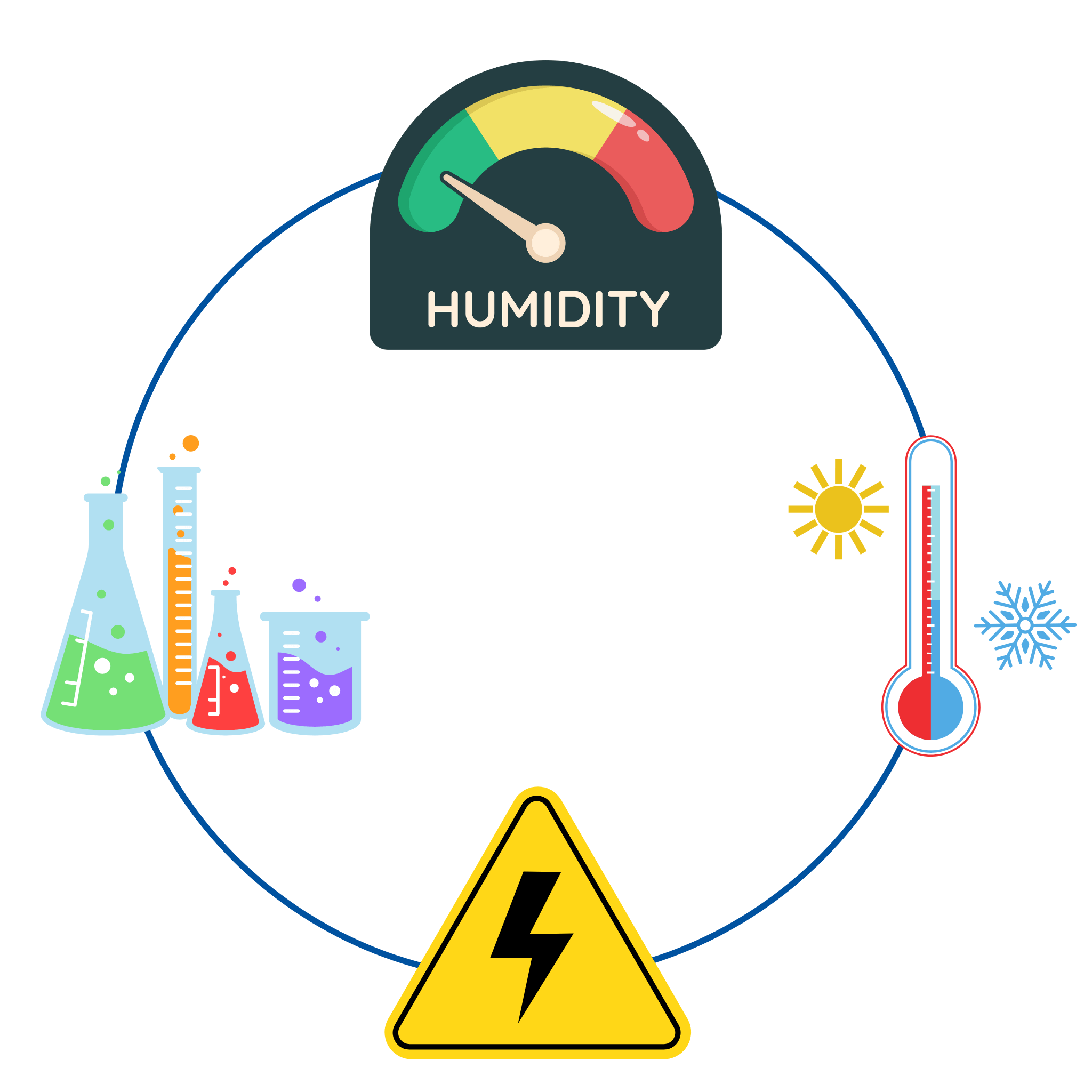

In addition to type and load capacity, the external conditions in which the Wheel or roller will be used must be considered. Key factors include:

- Operating temperature: some materials are suitable for high-temperature environments (e.g. industrial ovens), others maintain elasticity at low temperatures.

- Chemical agents: exposure to oils, solvents, acids, or aggressive substances requires specific materials with high chemical resistance.

- Moisture and water: wet or humid environments require corrosion-resistant materials or waterproof coatings.

- Hygiene requirements: for the food, pharmaceutical, and medical sectors, Wheels and castors must be easy to clean, corrosion-resistant, and compliant with hygiene regulations.

- Flooring type: smooth, rough, or uneven surfaces require different tread materials and designs to ensure comfort and safety.

Thorough analysis of these aspects ensures a reliable, safe, and durable product selection for each specific application.

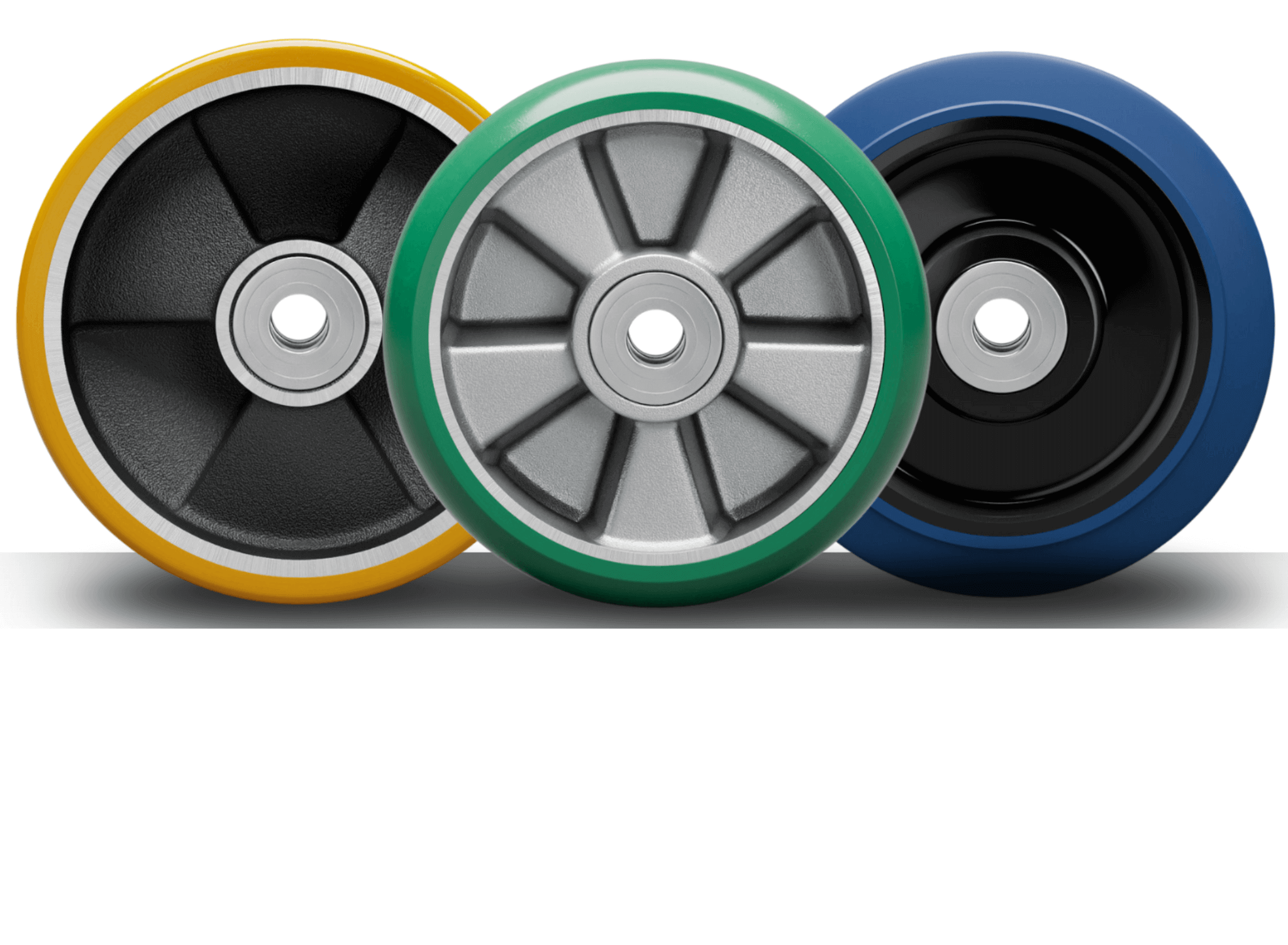

4. Selection of Wheel tread material

The tread material is decisive for ensuring optimal product performance in terms of rolling resistance, wear resistance, load capacity, and ride comfort. AVO offers a wide range of materials, each designed for specific applications:

- Polyurethane: high abrasion resistance, excellent elasticity, long service life, with variants for heavy loads, humid environments, chemical resistance, or antistatic properties.

- Solid and elastic rubber: good rolling properties, wear and heat resistance, superior comfort, with antistatic and non-marking versions available.

- Thermoplastic rubber (TPR): high elasticity, good chemical resistance, low rolling noise, suitable for indoor and light- to medium-duty applications.

- Polyamide 6 (Nylon®): lightweight, compression-resistant, chemically resistant, with low wear and excellent rolling properties. Also available in glass-fibre reinforced version.

- Cast iron and steel: suitable for high-temperature or heavy-duty applications, offering maximum mechanical strength and durability under extreme conditions.

Correct tread material selection ensures efficiency, safety, and reliability in every field of use.

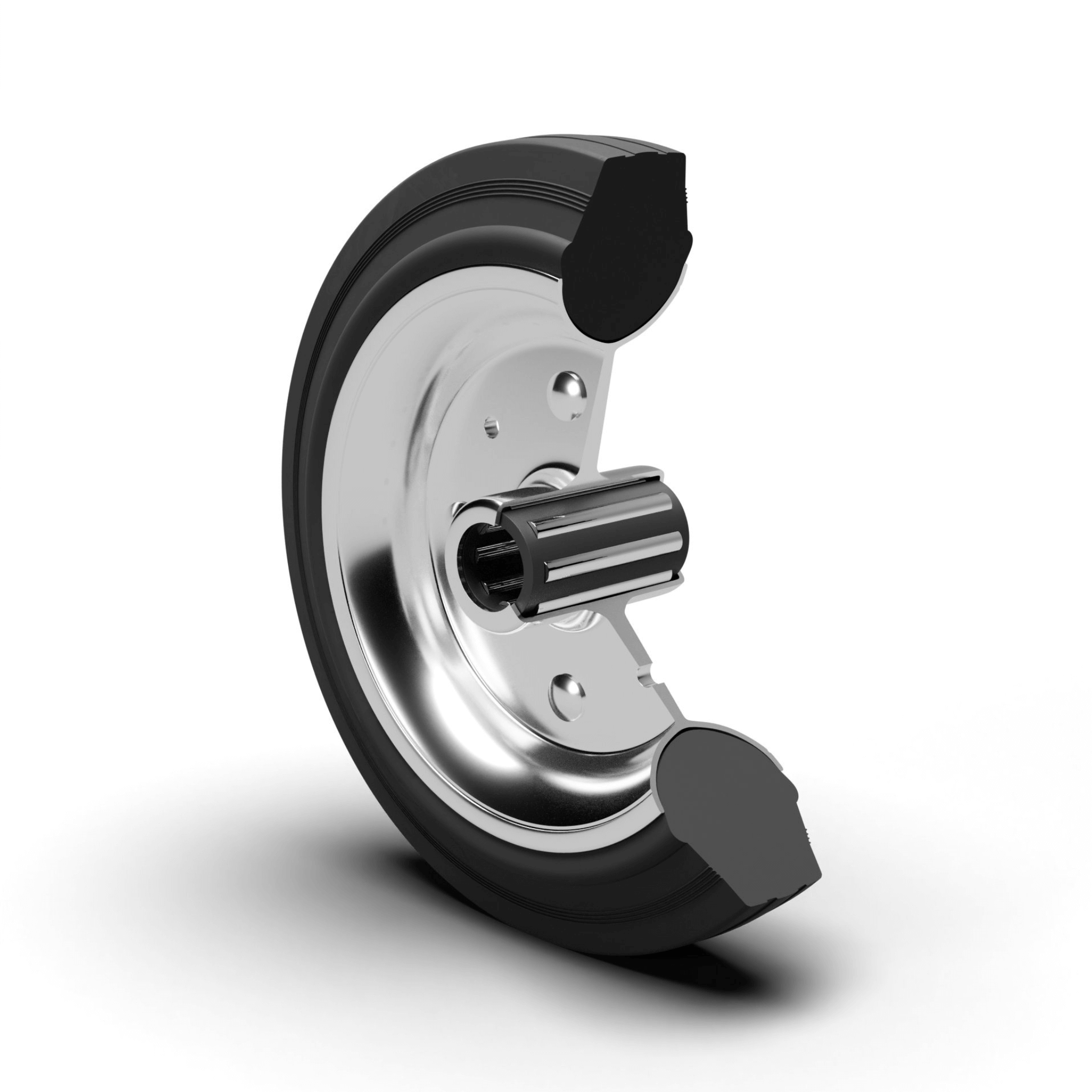

5. Hub type selection

The hub is the central element enabling Wheel rotation on the axle. The hub type directly influences rolling properties, load capacity, maintenance, and service life. Main options include:

- Plain bore: simple and economical, the axle is mounted directly into the bore. Suitable for light loads and low-speed applications.

- Bushing: made of self-lubricating nylon or other technical materials, provides good rolling properties, corrosion resistance, and low maintenance. Ideal for moderate speeds and intermittent use.

- Roller bearing: cylindrical rollers reduce sliding friction into rolling friction, allowing heavy loads to be moved with reduced effort. Also available in stainless steel.

- Ball bearing: the most advanced solution, offering excellent rolling performance even at high speeds and heavy loads. Available in standard or stainless versions, maintenance-free thanks to permanent lubrication.

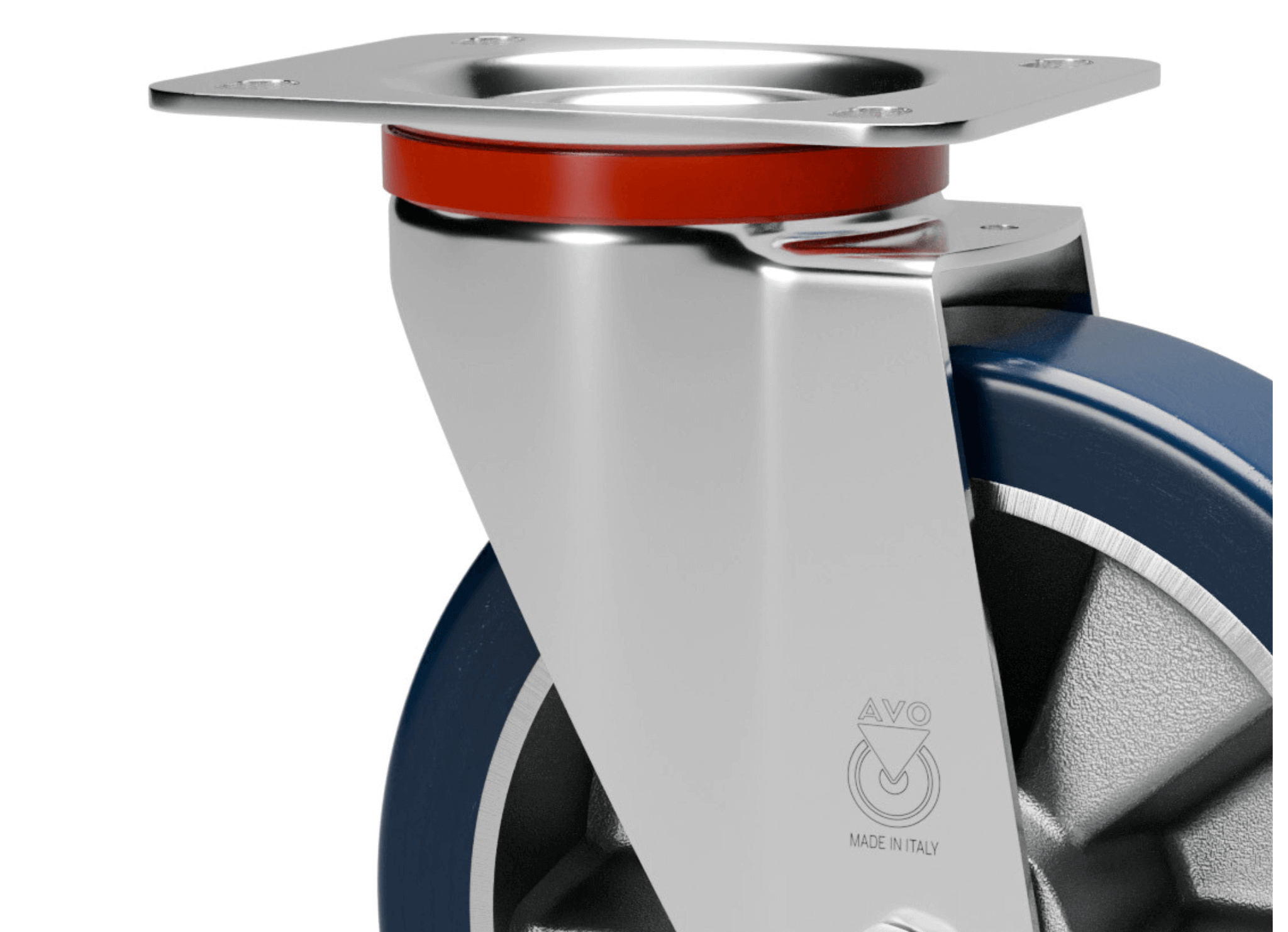

6. Selection of bracket, fitting type and accessories

The final step is to select the bracket, the appropriate fitting system, and any accessories.

- Brackets

Available in swivel (for maximum maneuverability), fixed (for stability and straight-line travel), or with integrated locks (parking or directional brakes). The choice depends on available maneuvering space, load type, and intended use. - Fittings

Main options include top plate, bolt hole, plain stem, threaded stem, and expanding stem. Each type meets specific mounting needs depending on the trolley or equipment structure. - Accessories

Enhance functionality, safety, and ergonomics: thread guards protect against debris, foot guards improve operator safety, directional locks stabilize straight-line movement.

The correct combination of these elements ensures the safest, most efficient, and most durable solution for any application.

For further technical details or to request tailored advice: